AF AG AR Coatings for TFT LCD Displays

Table of Contents

Introduction: The Critical Importance of LCD Panel Coatings

TFT LCD display glass coatings are like makeup for women – they not only make LCD panels and display screens more attractive but also provide anti-oxidation, acid-alkali resistance, and UV protection. In today’s appearance-focused era, LCD display surface coatings are absolutely essential! However, glass coatings come in various types, each serving different purposes. This comprehensive guide focuses on AF, AG, and AR coating technologies for TFT LCD displays, ensuring you understand their differences and applications.

Core Concepts of LCD Display Coating Technologies

To better understand these advanced coating technologies, we first need to explore their definitions and working principles for LCD panel applications.

AF Coating: Anti-Fingerprint Guardian for TFT LCD Display

Definition: AF stands for Anti-fingerprint coating, specifically designed for LCD display surfaces. Typically composed of SiO2+AF materials (DON, M4, Dow Corning AF materials), applied using vacuum evaporation coating methods on TFT LCD display panels.

Working Principle: AF anti-fingerprint LCD display glass utilizes lotus leaf principles, applying nanoscale chemical materials on the LCD panel outer surface to minimize surface tension. This reduces dust-glass surface contact area by 90%, providing strong hydrophobic, anti-oil, and anti-fingerprint capabilities, keeping TFT LCD display screens clean and bright for extended periods.

Compatible Materials: Various glass types and organic materials including PC, PMMA, PET for LCD display applications.

AR Coating: Transparency Enhancement Expert for LCD Panels

Definition: AR means Anti-reflection coating, designed to improve LCD display transparency. This technology enhances TFT LCD display light transmission while reducing LCD panel reflection to achieve optimal transparency. Multiple material options available, typically using alternating high-low refractive index materials, applicable through vacuum evaporation or magnetron sputtering for LCD display manufacturing.

Working Principle: When light travels from optically thin to optically dense materials, reflected light experiences half-wave loss. After applying AR coating on LCD display glass, surface reflected light has a path difference of exactly half wavelength compared to pre-coating surface reflection. Front and rear surface reflections cancel out, effectively increasing transmitted light energy for TFT LCD displays. Dual-side coating can simultaneously reduce reflection on both LCD panel surfaces.

Compatible Substrates: Glass, acrylic (PMMA), PC, CR39, and other organic glass materials suitable for LCD display applications.

AG Coating: Anti-Glare Visual Optimizer for TFT LCD Display

Definition: AG stands for Anti-glare coating, engineered for LCD panel glare reduction. This technology processes LCD display glass surfaces (single or double-sided) to achieve multi-angle diffuse reflection, improving TFT LCD display viewing angles, reducing ambient light interference, and minimizing screen reflection. Applied using spray coating + baking methods with SiO2 colloidal solutions on LCD panels.

Working Principle: Through light scattering and diffuse reflection, AG coating reduces reflection to prevent glare and eye strain, creating clear transparent visual space for enhanced TFT LCD display viewing experience.

Compatible Materials

| Coating Type | Compatible Substrates |

|---|---|

| AF Coating | Glass, PC, PMMA, PET, organic glass |

| AR Coating | Glass, acrylic (PMMA), PC, CR39, organic glass |

| AG Coating | Glass, various transparent substrates |

Manufacturing Process Details for LCD Display Coatings

Understanding basic principles leads us to explore specific manufacturing processes for these LCD panel coating technologies.

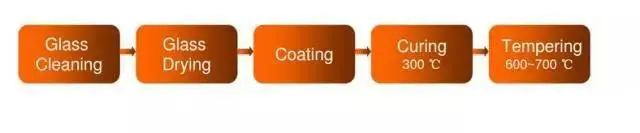

AF Coating Process for TFT LCD Display

The anti-fingerprint treatment process for LCD display applications is precise and straightforward:

- Pre-treatment: Remove oil, moisture, and contaminants from LCD panel surfaces using mild alkaline cleaners or solvents. Ultrasonic cleaning provides superior results for TFT LCD display preparation.

- Coating Application: Apply AF solution to LCD display surface for film formation

- Baking: After coating TFT LCD display panels, place in oven (120°C, 30 minutes), adjusting parameters based on specific LCD panel requirements

- Cleaning: Final cleaning and packaging of coated LCD display products

AR Coating Process for LCD Panels

Notably, all three coating processes for LCD display applications follow similar patterns, differing mainly in coating methods and chemical solutions. AR coating process for TFT LCD displays:

Coating Process Comparison

| Process Step | AF Coating | AR Coating | AG Coating |

|---|---|---|---|

| 1. Preparation | Alkaline/solvent cleaning | Surface cleaning | Surface preparation |

| 2. Application | AF solution coating | Multi-layer deposition | Spray coating |

| 3. Treatment | 120°C, 30 min baking | Curing process | Baking process |

| 4. Finishing | Final cleaning | High-temp tempering | Quality control |

| 5. Packaging | Product packaging | Product packaging | Product packaging |

Product Characteristics and LCD Display Applications

Different coating technologies provide distinct functional characteristics, leading to varied applications in LCD panel and TFT LCD display industries.

AF Coating: User-Friendly Protection for TFT LCD Display

Product Characteristics:

- Anti-pollution: Prevents fingerprints and oil stains on LCD display surfaces, easy to clean

- Scratch Resistance: Smooth surface texture, comfortable touch, difficult to scratch LCD panels

- Thin Film: Excellent optical performance without altering original TFT LCD display textures

- Wear Resistance: Genuine durability for long-term LCD panel protection

Application Fields: Primarily used for smartphones, tablets, televisions, LED displays, and various TFT LCD display screens in consumer electronics.

AR Coating: Professional Performance Leader for LCD Panels

Product Characteristics:

- High Transmission: Nanoscale optical coating technology increases ultra-clear LCD display glass light transmission by 2-3%

- Durability: Maintains performance for 25 years in harsh environments for outdoor LCD panels

- Anti-condensation: Significantly suppresses condensation formation on TFT LCD display surfaces

- Scratch Resistance: Increases hardness by 1H level for enhanced LCD panel protection

- Water Repellent: Water droplets achieve >110° contact angle on LCD display surfaces, automatically sliding off tilted panels without affecting vision

- Easy Cleaning: Reduces contamination by 80%, extremely easy maintenance for TFT LCD displays

Application Fields: Widely used in automotive windshields, solar photovoltaic industry (solar panels), range hoods, outdoor large advertising LCD displays, and professional TFT LCD display applications.

AG Coating: Comprehensive Visual Experience Enhancement for LCD Display

Product Characteristics:

- IR Reflection: Reduces infrared light transmission through LCD panel surfaces to minimize indoor IR radiation

- Enhanced Transmission: Reflects infrared while enhancing other light source transmission, maintaining optimal TFT LCD display illumination

- Anti-glare: Converts direct light through diffuse reflection (AG coating essence) to reduce harsh light stimulation for LCD display viewers

Application Fields: AG coating offers the broadest application range for LCD panel technologies:

- Premium art galleries and museums for precious artwork frames, ensuring long-term preservation and fade prevention

- Museums and archives for valuable artifact protection with specialized LCD display cases

- Electronic whiteboards, DLP/LCD touchscreens, DLP/LCD video walls with high transmission and anti-glare properties

- Precision instrument screens, medical equipment windows, LCD display monitors, electronic product windows

- Restaurant menu boards (KFC, McDonald’s) ensuring clear visibility without lamp reflection on LCD displays

- Airport and hotel information signs, indicator screens, and various TFT LCD display applications

Conclusion: Selecting Optimal Coating Technology for LCD Display Applications

Through comprehensive analysis, AF, AG, and AR coating technologies each offer unique advantages for TFT LCD display applications. AF coating focuses on daily usability convenience, AR coating pursues professional high-performance applications, while AG coating excels in visual experience enhancement. In practical LCD panel applications, selecting appropriate coating technology depends on specific usage scenarios and functional requirements. Sometimes combining multiple technologies achieves optimal results for advanced TFT LCD display systems.