TFT LCD and OLED Display Aging: The Importance of the Burn-in Test

Table of Contents

TFT LCD and OLED Display Aging: The Importance of the Burn-in Test

In today’s fast-paced world of technological innovation, the display screen has become one of the most vital components of any electronic device. Whether it’s a TFT LCD display or an OLED display, a screen’s quality and durability are paramount. This is where the burn-in test becomes crucial—it’s the key to guaranteeing that a display panel can maintain its excellent performance even after prolonged use.

Imagine a scenario where a brand-new device with a vibrant TFT LCD display starts to show noticeable signs of aging, such as a decrease in brightness or color fading. Or, for an OLED display, imagine permanent ghosting or “burn-in” where static images leave a permanent mark. These issues not only create a poor user experience but also erode consumer trust. Therefore, for manufacturers, the screen aging test is essential. It directly impacts product quality and market competitiveness. By performing these tests, manufacturers can proactively identify potential issues, optimize production processes, and select the highest quality raw materials. This ensures that every device leaving the factory is equipped with a durable, high-quality screen, which in turn boosts brand reputation, enhances user satisfaction, and drives sales.

Meticulously Built Testing Environment: Simulating Real-World Conditions

To accurately simulate the aging process of a device’s screen under real-world conditions, a meticulously crafted testing environment is required. This environment must account for several critical factors to ensure the validity and reliability of the LCD test results.

First and foremost, temperature is a crucial variable that accelerates screen aging. To observe noticeable changes in a shorter timeframe, the testing environment is typically set to a relatively high temperature, often within the range of 30°C to 50°C. Humidity is also a significant factor; a damp environment can cause internal electronic components to become moist, affecting screen performance. For this reason, humidity is strictly controlled within an ideal range, such as 30% to 60%. Additionally, prolonged exposure to strong light accelerates the aging of the screen’s backlight, leading to a faster decrease in brightness. The test environment therefore uses specialized high-intensity light sources to simulate these conditions with specific light intensity and durations.

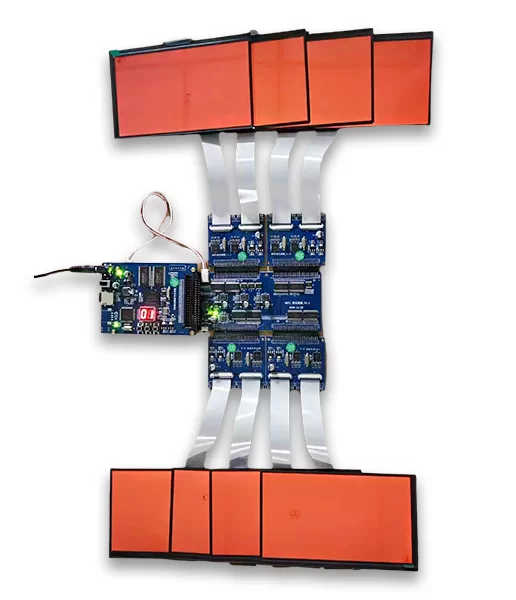

Furthermore, professional screen aging testing equipment is indispensable. This equipment can precisely control environmental parameters and monitor key performance indicators like brightness, contrast, and color saturation in real-time. During the burn-in test, the display panel remains lit on a specific fixture to mimic its normal working state. The equipment continuously records performance data at various time intervals, which is then used for in-depth analysis.

Comprehensive Test Items and Methods: A Multi-Dimensional Assessment

-

The new device screen aging test includes a variety of critical performance indicators, evaluated using scientific and systematic methods. This process is a vital part of the LCD test.

- Brightness Test: Brightness is a key measure of screen quality. A professional luminance meter is used to measure the screen’s initial brightness. Then, the brightness is measured at specific intervals (e.g., every 100, 200, or 500 hours) throughout the test. By comparing this data, manufacturers can understand the rate of brightness decay. If the decline exceeds a predefined standard, it indicates a durability issue.

- Color Saturation Test: Color saturation determines the vibrancy of the screen’s colors. A professional color analyzer is used to capture or read the screen’s standard color patterns. By repeating this process over time, manufacturers can analyze changes in color data. A gradual decrease in color saturation suggests a component or material issue that needs to be addressed.

- Contrast Test: Contrast defines the clarity between the light and dark parts of an image. A high-contrast test pattern, such as a black-and-white checkerboard, is displayed on the screen. A contrast meter then measures the luminance of the white and black areas to calculate the contrast ratio. A decline in contrast over time indicates a weakening ability to distinguish fine details, which can negatively impact the user’s viewing experience.

- Dead Pixel Test: Dead pixels are a common screen defect. During the burn-in test, special software is used to display full-screen solid colors (red, green, blue, etc.). The screen is then carefully inspected for any bright or dark spots that don’t match the background color. If the number of dead pixels increases or their distribution becomes denser, the screen’s quality needs to be re-evaluated to ensure it meets product standards.

Conclusion: The Screen Aging Test Drives Industry Progress

The new device screen aging test is a vital and indispensable part of the display manufacturing process. It’s the cornerstone for ensuring product quality, enhancing user experience, and maintaining a positive brand image. By establishing a rigorous testing environment, employing scientific methods, and conducting in-depth data analysis, manufacturers can fully understand how their screens age and pinpoint the contributing factors.

Based on these insights, manufacturers can take proactive steps to boost the screen’s anti-aging capabilities—from optimizing material selection and improving manufacturing processes to implementing software enhancements and educating users. The existence of industry standards and specifications provides a consistent benchmark for quality, pushing the entire industry to continuously improve.

Looking ahead, screen aging tests will become more precise, efficient, and intelligent. They will provide stronger support for advancements in screen technology, ultimately leading to more durable and high-quality display products for consumers and fostering the healthy and sustainable development of the smart display industry.