AF Coating: Clarity and Protection for TFT LCDs

Table of Contents

AF Coating (Anti-fingerprint Coating) Process: A Comprehensive Guide

The Anti-fingerprint Coating (AF Coating) process is a specialized surface treatment vital for modern electronic displays. It represents a significant advancement in enhancing the functionality and durability of consumer electronics, particularly those featuring

TFT LCD displays and responsive touch screens.

1. Core Definition and Function: Enhancing the User Experience of TFT LCD Displays

AF Coating, fully known as Anti-fingerprint Coating , is a nanoscopic surface treatment alied to materials like glass or organic substrates. Its principal objective is to dramatically improve the tactile user experience of touch screens like TFT LCD displays while simultaneously ensuring enhanced display clarity.

The Foundational Role of General Coating:

· Before delving into the specifics of the AF film, it is essential to understand the general functions of any protective coating:

· Improving Optical Performance: Coating can alter an object’s optical properties, such as increasing light transmittance, reducing unwanted reflections, and eliminating color distortion (chromatic aberration).

· Reducing Reflection: By lowering the surface’s reflectivity, coating enhances the efficiency of light transmission, which is crucial for achieving clearer visual effects and vibrant displays.

· Enhancing Wear Resistance: The alication of a coating significantly increases the substrate’s surface hardness, allowing it to effectively resist mechanical damage, scratches, and everyday wear and tear.

The Principle of AF Coating: Emulating the Lotus Effect The efficacy of

AF Coating is rooted in biomimicry, specifically the Lotus Effect. This principle involves alying a specialized nano-scale chemical material—typically a composite incorporating SiO2 and perfluoropolyether —to the substrate surface. This specialized material drastically lowers the surface tension.

The reduced surface energy minimizes the contact area between the surface and contaminants like dust and fingerprints by over 90%. Consequently, the coating exhibits pronounced hydrophobic (water-repelling, with a water drop contact angle ≥110∘) and oleophobic (oil-repelling, with an oil drop contact angle ≥60∘) characteristics, providing effective anti-fouling and anti-fingerprint protection.

Wide-Ranging Alications: Protecting Mobile Phone Screens, Tablets, and Camera Lenses

Owing to its superior anti-fingerprint and protective attributes, AF film is extensively used across various electronic devices:

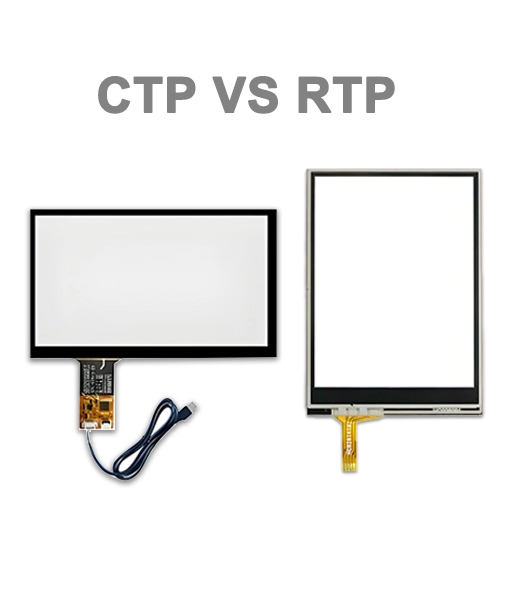

· Mobile Phone Screen Protection: As smartphones are the most frequently handled devices, a

· lying AF film to the screen effectively minimizes smudges and fingerprints. This enhances both the screen’s clarity and the overall responsiveness of the touch functionality.

· Tablet PC Screen Protection: Similar to mobile phones, coating tablet screens reduces blemishes, thereby improving the clarity of the display screen and ensuring smooth touch operation.

· Camera Lens Protection: AF film can also be alied to high-precision camera lenses. This minimizes the impact of fingerprints and smudges on the lens surface, which is critical for achieving consistently clearer and higher-quality photographic outcomes.

The AF Coating Process Flow and Core Technology

The fabrication of AF film involves a meticulous and rigorous multi-step coating process. This sequence of stages is designed to systematically modify and protect the base substrate.

The Systematic Preparation Process Flow:

1. Substrate Preparation (Base Material Preparation): The process begins with the thorough cleaning of the base material, typically a silicon substrate, to ensure complete removal of all surface dust and impurities.

2. Flattening Treatment (Leveling Treatment): This crucial step prepares the substrate for the coating. It involves either chemical treatment or immersion in a chemical solution to fill micro-pores and clear away any microscopic defects or unevenness. This process ensures a perfectly flat and uniform surface necessary for high-quality

TFT LCD panel coating.

3.Surface Coating (Coating):A specialized material solution is alied to the leveled base material to form an even, uniform layer. The final anti-fingerprint performance is significantly influenced by the precise control over the coating’s thickness and chemical composition.

4. Hardening Treatment (Hardening): To fortify the coating, the material is typically subjected to thermal processing. This step stabilizes the coating’s structure, substantially increasing its hardness and wear resistance , enabling it to effectively withstand scratches.

5. Surface Flattening (Surface Flattening): The concluding step involves polishing or a similar process on the coated surface. This final surface eliminates any minor residual unevenness, enhancing both the visual appeal and the smooth, sleek tactile sensation of the finished product.

6. Inspection and Packaging: The finished AF film undergoes a stringent quality inspection to verify the coating’s integrity. It is then packaged and sealed for distribution.

Conclusion: A Solution Ensuring Long-Lasting Screen Clarity

In conclusion, the AF coating process is a multi-stage manufacturing sequence, encompassing flattening treatment, surface coating, hardening treatment, and surface flattening. The successful implementation of this sophisticated process results in a significantly improved and protected substrate. The alication of AF film demonstrably elevates the user experience of touch screens and enhances display clarity, all while providing robust wear resistance and superior anti-fingerprint characteristics. Widely adopted across devices such as mobile phones, tablets, and cameras, AF coating is essential for maintaining the long-term clarity and protection of electronic displays.